For decades, the core of inventory management has been the barcode scan—a simple, digital confirmation that an item is here, or it is there. While essential, this approach is a 20th-century solution struggling to keep pace with the complexities of 21st-century supply chains. The real challenge today isn’t just tracking what’s in stock; it’s managing the relentless stream of exceptions—supplier disruptions, shipping discrepancies, damaged goods, and unexpected costs—that break rigid, traditional automations and cause chaos in the warehouse and on the balance sheet.

The promise of a modern inventory management AI is not just a more predictive dashboard or a fancier report. The true transformation lies in moving beyond static data analytics to build truly self-learning business processes. It requires transforming your inventory system from a passive database into an intelligent, operational engine.

This guide is for leaders who want to build a resilient and autonomous supply chain. We will explore a new paradigm that goes beyond simple tracking. The goal is to demonstrate how a new class of inventory management AI can automate end-to-end workflows, intelligently handle exceptions by collaborating with human experts, and learn from their guidance to automatically refine and improve processes over time. This is about creating an ecosystem that doesn’t just report on what happened, but actively learns and adapts to what’s happening now.

The Fragility of Traditional Inventory Systems

Most companies still rely on a patchwork of systems that, while digital, are fundamentally static. Traditional retail inventory management software and enterprise ERP modules are excellent systems of record. They can tell you the expected quantity of an item in a specific location. However, they are not systems of action. They cannot reason, adapt, or independently resolve the messy, real-world problems that occur between the purchase order and the final stocking.

To bridge this gap, many have turned to Robotic Process Automation (RPA). But these rule-based bots are notoriously brittle. They are programmed to follow a script, and when a supplier updates their web portal or a shipping partner introduces a new type of document, the bot breaks. This leaves teams scrambling to manually fix the process, negating the very efficiency the automation was meant to create. This is a common failure point for any legacy retail inventory tracking system.

The cost of these exceptions is enormous. It’s measured in wasted hours of manual reconciliation, delayed shipments, inaccurate financial forecasts, and the risks of stockouts or overstocking. A truly effective inventory management AI must be designed to handle this chaos, not fail because of it.

What “Self-Learning” Truly Means for Inventory Management

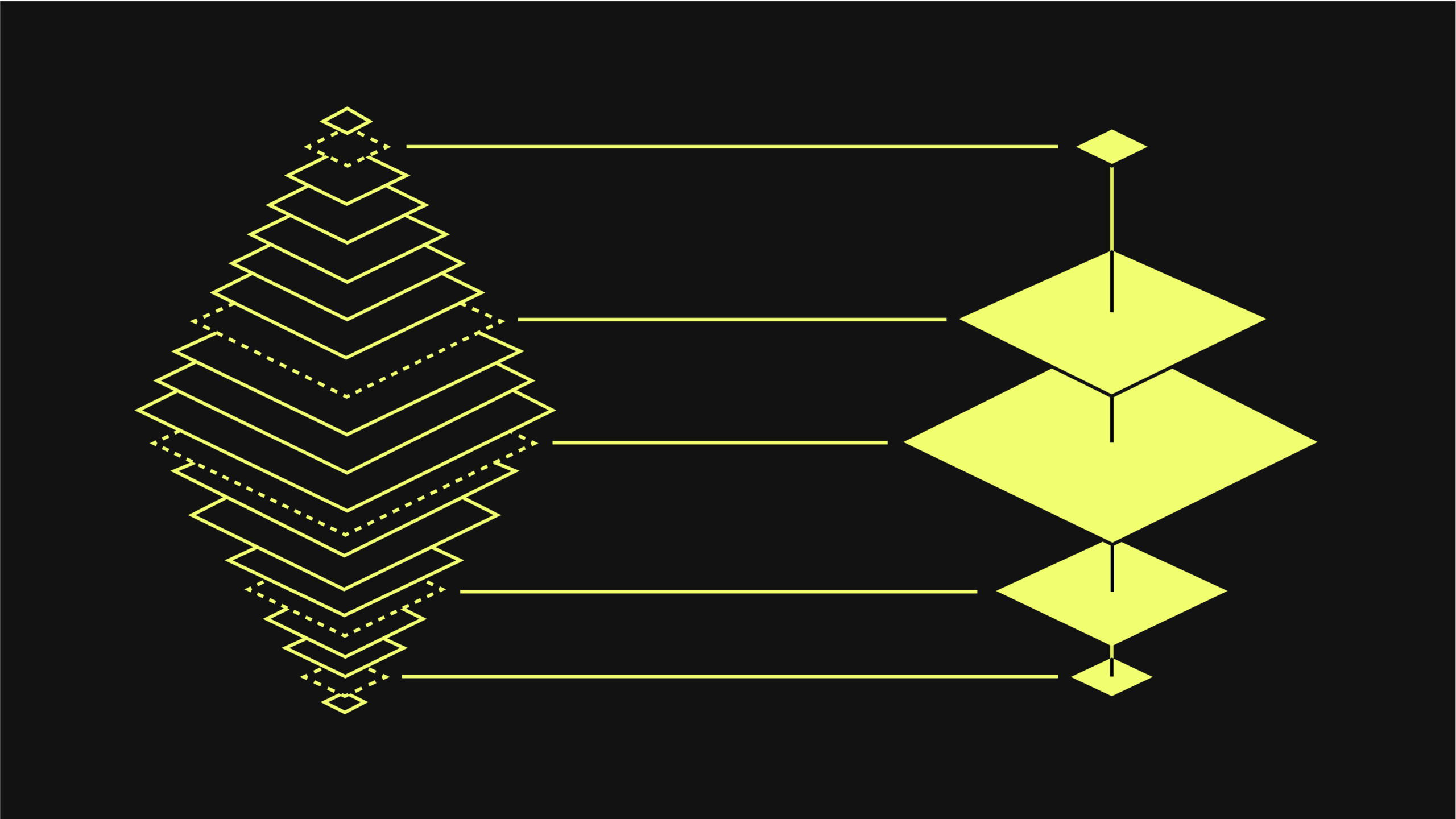

The term “self-learning” in the context of inventory management AI is often conflated with predictive forecasting. While predicting demand is valuable, it is only one piece of the puzzle. A truly self-learning system is an operational one. It is a system that learns the process of inventory management, not just the data.

This new paradigm of inventory management AI is defined by four key capabilities:

- Execute End-to-End Processes: It can autonomously manage entire workflows, such as orchestrating a three-way match between a purchase order, a goods receipt note, and a supplier invoice.

- Detect and Diagnose Exceptions: It uses AI reasoning to identify discrepancies in real-time. It doesn’t just see a number doesn’t match; it understands the business context of that mismatch.

- Collaborate with Human Experts: When an unknown exception occurs, the system doesn’t fail. It intelligently routes the problem to the right person, provides the context, and asks for guidance.

- Learn and Adapt: This is the core of a self-learning system. The inventory management AI learns from the resolution provided by the human expert. It incorporates that new knowledge into its process, so the next time the same exception occurs, it can handle it autonomously. This is where inventory management machine learning creates lasting value.

The Engine of a Self-Learning System: Natural Language and AI Reasoning

This intelligent, adaptive capability is powered by a new class of inventory management AI built on two core technological pillars:

- Natural Language: The most significant shift is the move away from complex code. A modern inventory management AI platform allows business users—the supply chain managers, finance professionals, and inventory planners—to build, manage, and modify their own automation workflows using plain English. This makes the system incredibly agile. When a process needs to change, an expert can simply describe the change, and the AI understands and adapts.

- AI Reasoning and Unstructured Data Processing: Unlike traditional bots, this AI can read and comprehend unstructured documents, such as PDFs, emails, and bills of lading. It can reason through the information it finds, identify exceptions, and execute complex business logic, making it the ideal engine for AI inventory optimization.

This combination creates a collaborative environment where the technology handles the repetitive work, and the human experts handle the novel exceptions, all while continuously making the system smarter. This is the foundation of any effective retail inventory tracking system.

A Self-Learning Retail Inventory Tracking System in Action

Let’s consider a practical example for a multi-store retailer. Their retail inventory management software is proficient at tracking stock, but the process of receiving goods is fraught with exceptions. Here’s how a self-learning inventory management AI transforms that process.

- Step 1 (Automated Execution): The inventory management AI is tasked with processing an incoming shipment for a popular product line across several stores, a core function of any retail inventory tracking system. It is set to perform a three-way match before authorizing payment.

- Step 2 (Exception Detection): The AI reads the unstructured bill of lading and the supplier’s invoice. It immediately detects two exceptions: the quantity received is 50 units short of the 1,000 units ordered, and the invoice includes a new, unexpected “expedited freight charge.” A traditional retail inventory tracking system would simply fail or flag a generic error.

- Step 3 (Intelligent Collaboration): Instead of failing, the inventory management AI pauses the process. It sends a message to the designated supply chain manager via Microsoft Teams, presenting the issue clearly: “Discrepancy found for PO #78910. Received 950 of 1000 units. Invoice includes a new ‘expedited freight charge’ of $750. Please advise on how to proceed with the three-way match and payment authorization.”

- Step 4 (Learning and Healing): The manager reviews the attached documents and instructs the AI in plain English: “The short shipment was pre-approved. Adjust the PO to 950 units. The freight charge is valid; approve it and map it to the ‘unplanned logistics’ cost center for future invoices from this supplier.” The inventory management AI not only completes the current task correctly but also learns this new rule. The next time this supplier uses an expedited freight charge, it will be processed automatically. The system has healed and improved itself. This is what the best retail store inventory management software should do.

This example of AI inventory optimization showcases a system that is not just automated but is also resilient and intelligent. This is the standard for any modern inventory management software for retailers.

The Strategic Benefits of Inventory Management AI

For CIOs and finance leaders, the shift to a self-learning inventory management AI delivers profound strategic benefits that go far beyond the warehouse floor.

- Unprecedented Resilience: The system adapts to real-world supply chain disruptions rather than breaking because of them, creating a more robust and reliable operation.

- Drastic Efficiency Gains: It eliminates countless hours of manual exception handling and reconciliation, freeing up teams to focus on more strategic activities like vendor negotiation and AI inventory optimization.

- Enhanced Financial Control: By intelligently processing invoices and identifying unexpected costs, the inventory management AI provides a more accurate and real-time view of the cost of goods sold and overall profitability.

- A Dynamic System of Record: Every time the AI learns from a human expert, it captures that “tribal knowledge.” The automated processes become a living, auditable record of how your organization actually handles its inventory, preserving institutional wisdom.

The Way Forward

The era of managing inventory through static reports and brittle bots is over. The future of the supply chain will not be defined by how well a business can track what it has, but by how intelligently its processes can adapt to the unpredictable reality of what happens next. The move from a passive system of record to a dynamic, self-learning operational engine is the single most important transformation leaders can make. By embracing an inventory management AI that learns from your experts and automates the chaos of exceptions, you are not just optimizing a function; you are building a truly autonomous and resilient supply chain ready to face any disruption.