The modern manufacturing enterprise is a study in contrasts.

Walk the production floor, and you see the bleeding edge of Industry 4.0: Autonomous Mobile Robots (AMRs) navigating aisles, predictive maintenance sensors monitoring spindle vibration, and Digital Twins modeling production flows.

Walk towards the finance department, and the picture changes. You see highly paid Accounts Payable (AP) clerks manually keying data from PDF invoices into SAP or Oracle. Or worse, you see them “babysitting” a suite of broken software bots.

For the last decade, manufacturers were sold a promise: Invoice Processing Automation via Robotic Process Automation (RPA) would eliminate manual data entry. The pitch was simple- teach a bot to read the invoice, and it will do the work.

But in the complex reality of manufacturing, this promise has broken down. Invoice processing for manufacturers is not a simple data entry task; it is a complex reconciliation challenge involving physics, logistics, and volatile supply chains.

When invoice processing solutions rely on static templates, they don’t just create IT tickets- they create supply chain risk. If a bot crashes because a vendor changed a font, that vendor doesn’t get paid. If the vendor doesn’t get paid, raw materials don’t ship. If raw materials don’t ship, the line stops.

This article explores why traditional RPA has failed the manufacturing sector and how the industry is moving toward a resilient, Neurosymbolic AI future.

The Unique Pain of Manufacturing AP

Why does automation that works for a law firm or a marketing agency fail in a factory? The answer lies in the complexity of the “Match.”

In a service business, an invoice is simple: “Consulting Services: $5,000.”

In manufacturing, an invoice is a logic puzzle. You must perform a 3-Way Match between:

- The Purchase Order (PO): What we asked for.

- The Goods Receipt Note (GRN): What the loading dock actually received.

- The Vendor Invoice: What we are being billed for.

These three documents almost never match perfectly.

The Unit of Measure Nightmare

The single biggest failure point for invoice processing for manufacturers is the Unit of Measure (UoM) mismatch.

- Scenario: Your procurement team orders steel by weight. The PO says “1,000 kg of Stainless Steel.”

- Reality: The supplier bills by the roll. The invoice says “10 Rolls of Steel (Standard Grade).“

To a human AP clerk, this is easy. They know (or check a spec sheet) that 1 Roll = 100kg. They do the mental math: $10 \times 100\text{kg} = 1,000\text{kg}$. The match is valid.

To a traditional RPA bot, this is a fatal error.

RPA relies on “Exact String Matching.” It looks at the PO (“1,000”) and the Invoice (“10”). It sees that $1,000 \neq 10$. It throws an exception.

This is one of the primary disadvantages of RPA in manufacturing. The bot has no semantic understanding of what it is processing. It doesn’t know what “Steel” is, nor does it understand the conversion between “Rolls” and “kg.”

Semantic Matching with Neurosymbolic AI

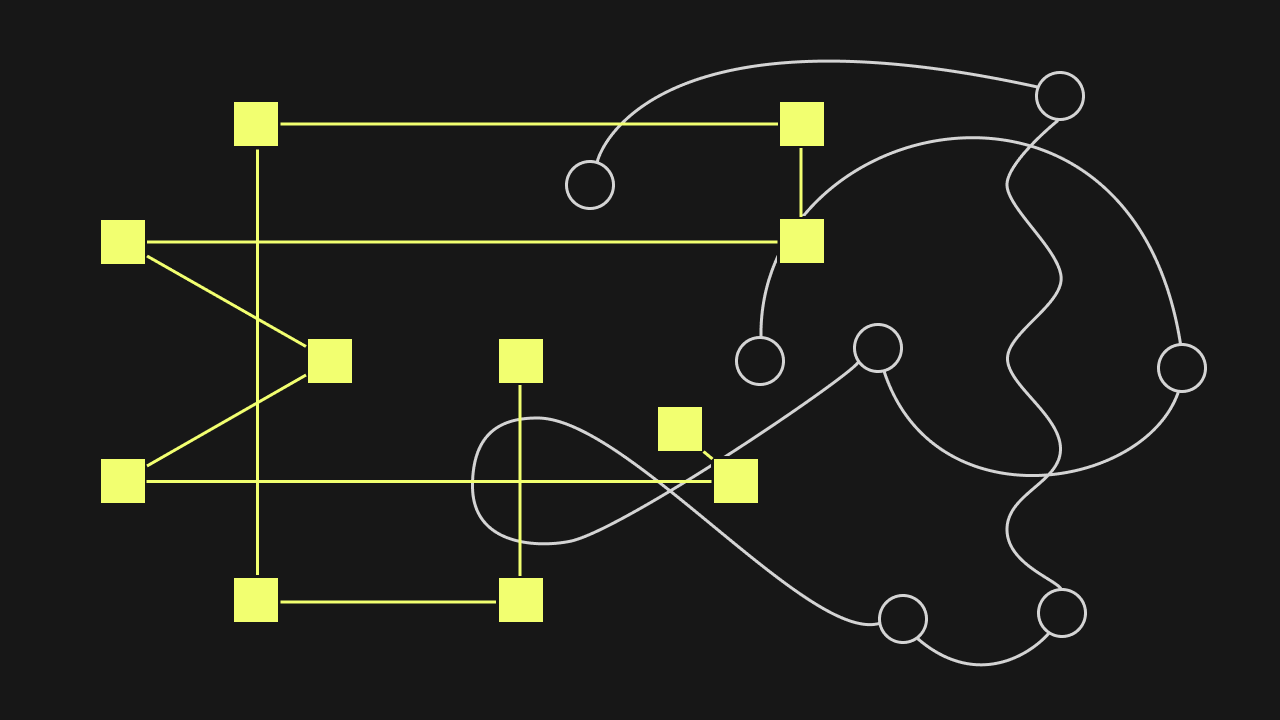

Kognitos approaches this differently by using Neurosymbolic AI.

- The Generative Brain (The Reader): It reads the invoice and understands the context. It recognizes that “Rolls” and “kg” are units of measurement for the same line item.

- The Symbolic Brain (The Calculator): It executes the logic. It can look up your internal Master Data to find the conversion factor (1 Roll = 100kg) and perform the math deterministically.

This allows Kognitos to automate the “Unit of Measure” problem that leaves RPA bots paralyzed.

Volatile Supply Chains Break Static Bots

The second major failure point is the Template Trap.

Legacy invoice processing automation tools work by memorizing the layout of a document. You teach the bot: “For Vendor A, the Total Amount is in Row 50, Column C.”

This works in a static world. But manufacturing supply chains are volatile.

- Vendors update their billing software (moving the data to Row 51).

- You switch suppliers due to a raw material shortage.

- A logistics provider adds a new Fuel Surcharge line item due to rising oil prices.

Every time one of these variables changes, the template breaks. The bot crashes.

In a manufacturing company with 5,000+ active vendors, maintaining these templates becomes a full-time job for the IT department. Instead of automating AP, you have simply traded “Manual Data Entry” for Manual Bot Maintenance. This is why many manufacturers find themselves in what analysts call “RPA Project Hell.”

Resilience via No-Template Extraction

Kognitos Agents do not use templates. They use computer vision and Large Language Models (LLMs) to read the document like a human does.

If a vendor sends a new invoice layout where the “Total” has moved to the bottom left, the Kognitos agent finds it- not because of coordinates, but because it understands the concept of a “Total.”

This shifts your AP function from Fragile (breaks on change) to Resilient (adapts to change). You no longer need to fear a vendor updating their ERP system; your automation handles it instantly.

From Exception Queue to Learning Loop

One of the hidden disadvantages of RPA is the creation of the Exception Queue

When a bot fails (due to a UoM mismatch or a template break), it dumps the invoice into a queue for humans to fix. In many manufacturing firms, this queue contains 40-60% of all invoices. This isn’t automation; it’s just “digital triage.”

But in the Kognitos model, an exception is not a failure- it is a lesson.

Conversational Exception Handling

Imagine a scenario involving “Price Creep.”

A logistics vendor submits an invoice that is $50 higher than the PO.

- RPA Bot: Flags “Variance > $0.” Stops. Dumps to queue.

- Kognitos Agent: Investigates. It sees a line item for “Emergency Rush Fee.” It pauses and pings the Logistics Manager on Slack/Teams.

Agent: “I found a $50 variance on the DHL invoice labeled ‘Rush Fee.’ The PO didn’t specify this, but the delivery date was moved up. Should I approve?”

Manager: “Yes, we requested expedited shipping. Approve it.”

Agent: “Understood. Approving payment. Do you want me to allow ‘Rush Fees’ up to $100 for this vendor in the future?”

When the manager says “Yes,” the AI learns. It updates its own logic. The next time a similar rush fee appears, the agent handles it autonomously.

This transforms the AP process from a reactive “clean-up” operation into a proactive “cost control” mechanism. The AI catches the creep, asks for context, and encodes the tribal knowledge of the manager into the system logic.

Why This Matters: Supply Chain Risk

Ultimately, invoice processing for manufacturers is not about saving a few cents on processing costs. It is about protecting the supply chain.

When AP automation fails, invoices get stuck. When invoices get stuck, payment terms are missed.

- Credit Holds: Strategic suppliers may put you on credit hold.

- Production Stops: If you can’t get the specialized resin because the vendor hasn’t been paid, the production line halts.

- Reputation Damage: In a tight market, suppliers prioritize customers who pay on time.

By relying on brittle RPA bots, Finance leaders are inadvertently introducing a single point of failure into the supply chain.

The Move to Intelligent Orchestration

The factory of the future cannot run on the finance tools of the past.

For Manufacturing CFOs, the path forward is clear. You must move away from invoice processing solutions that rely on rigid templates and blind data extraction. You need a system that understands the physics of your business- that knows a “Roll” is “100kg,” that understands a “Fuel Surcharge” is valid, and that can learn from your team.

Kognitos offers this capability through Neurosymbolic AI. It provides the auditability of a strict financial system with the flexibility of a human AP clerk.

Your supply chain is dynamic. Your automation should be too.